Swiss-Based Zünd Digital Cutting Systems

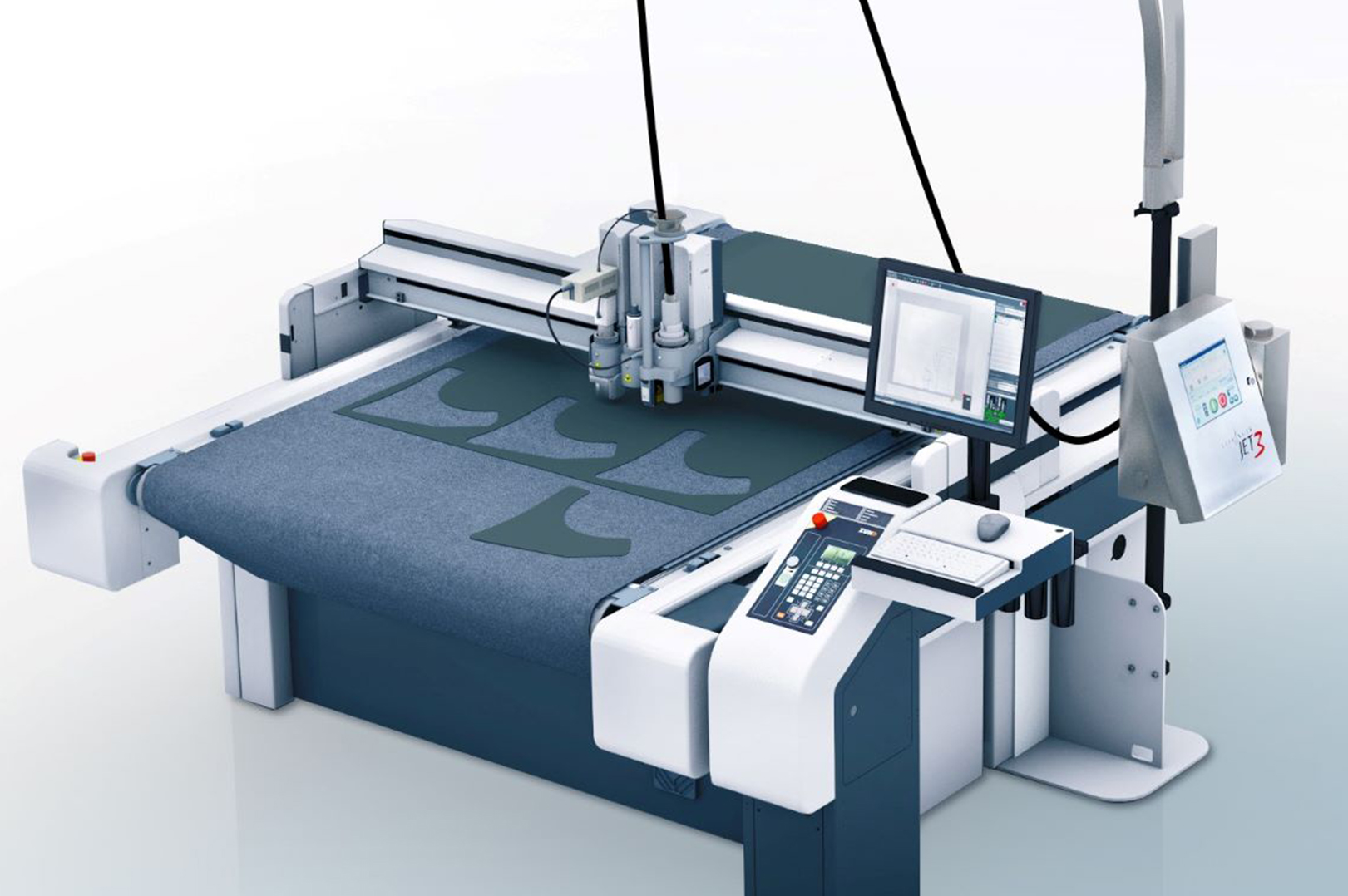

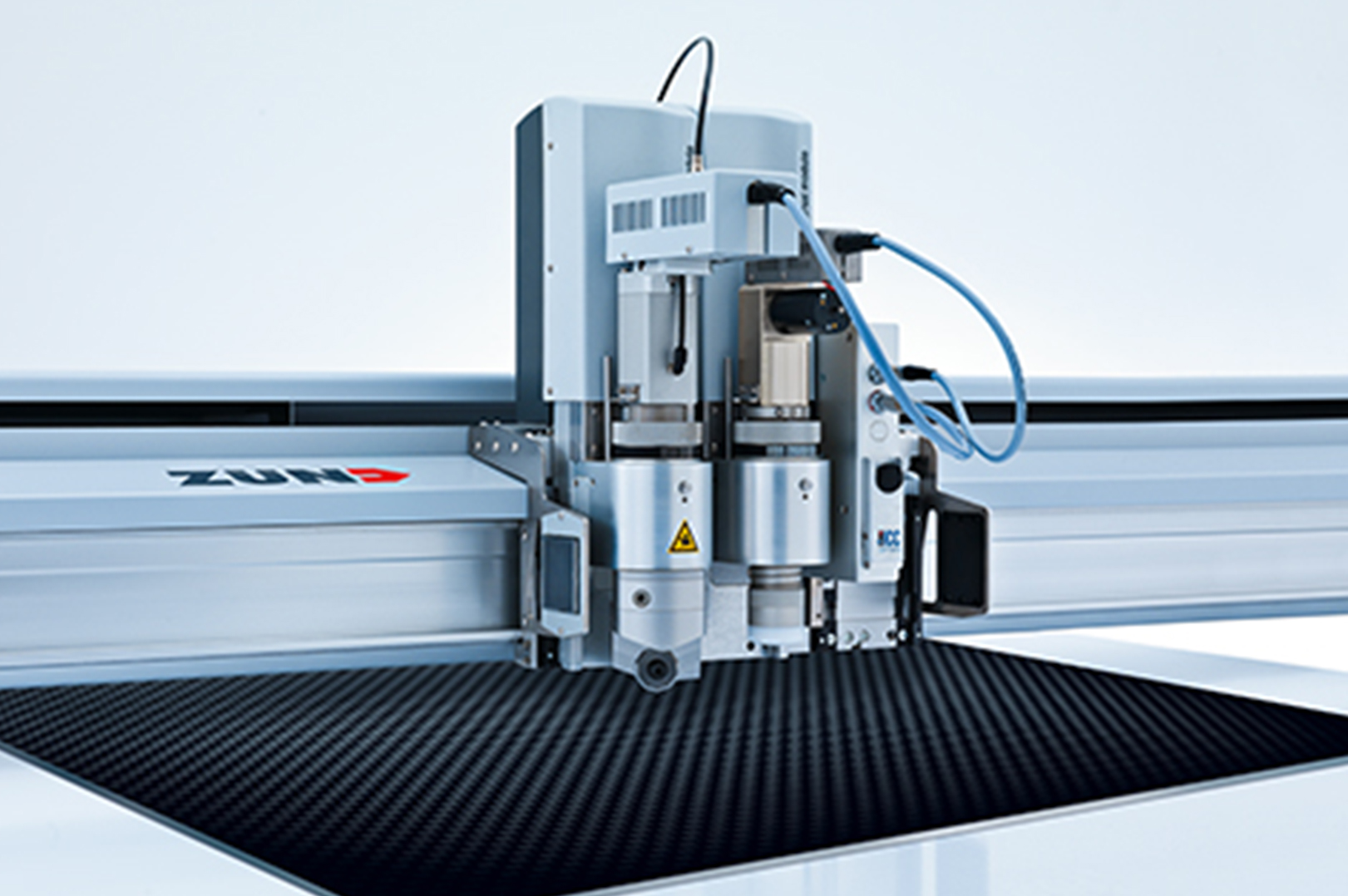

Swiss-based Zünd is a leading provider of digital cutting systems that are helping manufacturers in aviation and many other industries to optimize their production processes. The company's modular systems are designed for versatility and adaptability, enabling manufacturers to customize each system to suit their specific workflows.

One of the key benefits of Zünd's digital cutting systems is the ability to fully automate production workflows, from material handling to cutting and kitting.

This automation not only streamlines production processes, but also provides greater transparency and traceability throughout the production process, ultimately enhancing efficiency and profitability.

When market demands change, and companies choose to pivot to produce a different product or work on another application, that's another area where Zünd shines, explains Beatrice Drury, marketing & communications manager at Zund America, Inc.

“They only need to buy an additional tool," she explains. "They don't have to buy a whole new machine, and that's really beneficial."

Upon selecting a Zünd digital cutting system, a customer must first determine the machine size that will accommodate both their current and potential future needs. Once the appropriate cutting system or systems have been chosen, the modularity of the system comes into play, offering customers the flexibility to use a variety of tools and automated material handling solutions.

The integration of robotics, for example, is an important aspect of automated material handling, which can be considered part of the overall workflow. While not solely software-based, this aspect also involves essential hardware components, such as robotic arms or other automated mechanisms. Zünd’s systems accommodate a range of material feeding options, from simple sheet feeders, to robotic load/offload devices, and more advanced roll feeders.

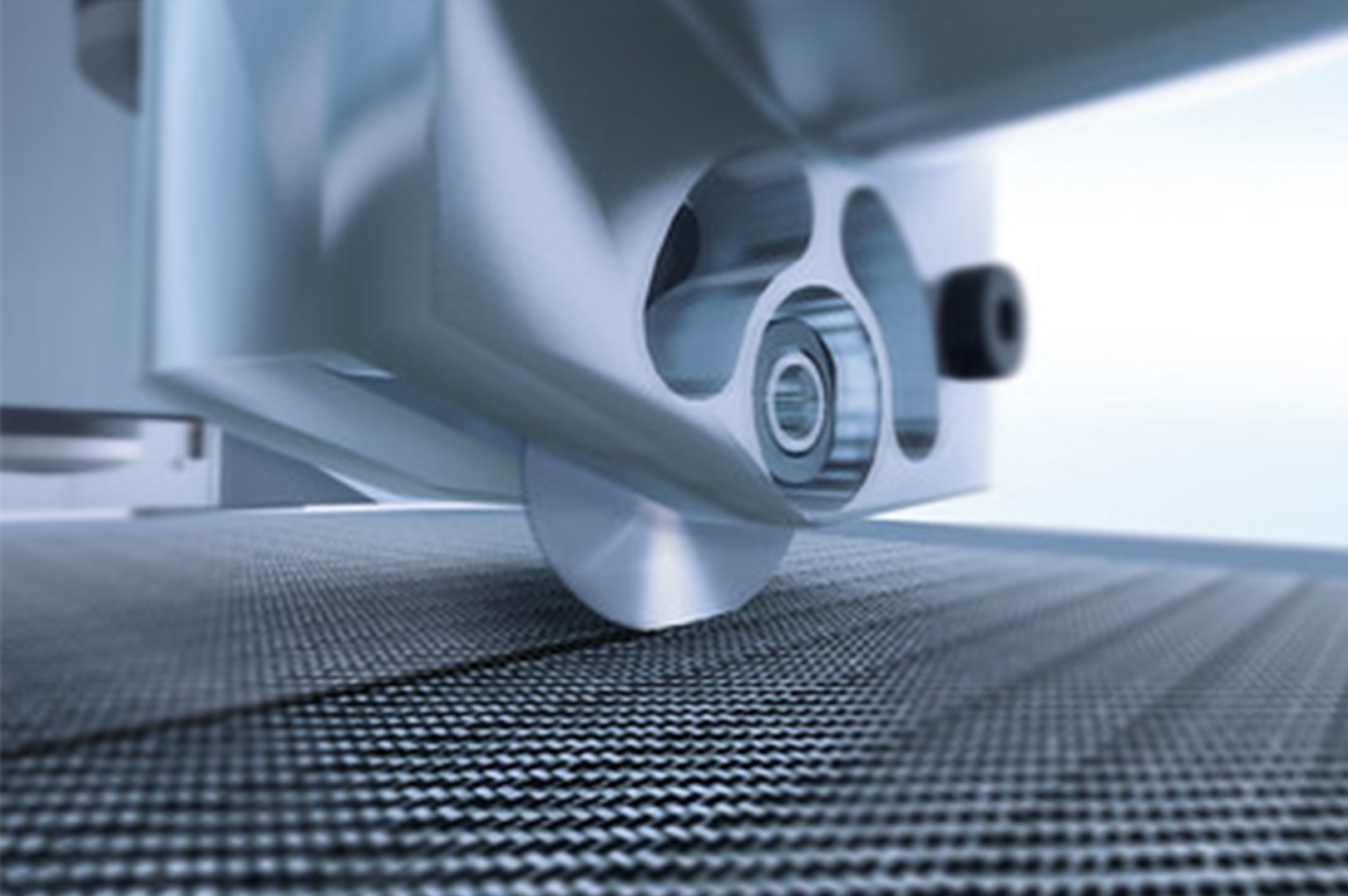

When dealing with materials like stretch fabrics, for instance, a specialized type of roll feeder, known as a spreader, can be used. This device ensures that the material is fed onto the machine without causing distortions, which can occur when feeding stretchy materials due to their elastic nature. This level of adaptability and customization allows customers to tailor their Zünd cutting system to suit their unique production requirements.

Zünd machines are frequently utilized for processing a diverse range of materials, such as technical textiles, carbon fiber, carpet, leather and foam, among others. These materials are commonly used for a wide variety of purposes, including gaskets, sound dampening, insulation, graphics, interiors, and numerous other applications.

For processing composites, Zünd recently introduced a heat-seal module (HSM) tool that heats thermoplastic material to essentially fuse it along the cutline before the cutting process in order to stop fraying, Drury says. “We have spent a lot of time and effort on really finding whatever challenges customers have in any application that they do and resolving those for them,” she adds.

For many applications involving costly materials, Zünd also specializes in maximizing throughput and yield through functions such as automated nesting, which enables manufacturers to optimize material usage and reduce processing time and waste.

Aviation and aerospace are two industries that demand the highest levels of precision and quality, making Zünd's digital cutting systems a perfect fit, Drury says. The company's cutting solutions are ideal for manufacturing critical components, such as aircraft interiors and exterior parts, and can help aviation manufacturers to optimize their production processes and increase profitability.

By streamlining the entire production process, manufacturers can reduce costs, improve quality, and increase profitability.

The success of Zünd's digital cutting systems is evident in its partnerships with some of the world's leading manufacturers. For example, Pilatus Aircraft AG, relies on Zünd's digital cutting technology to produce its latest business jet, the PC-24. Pilatus has a long history of manufacturing aircraft, dating back to the PC-6 Porter in 1959. The PC-6 was a sturdy, all-metal universal aircraft that was assembled exclusively by hand. As the company grew, it began using carbon fiber parts to reduce weight and increase durability. Today, the PC-24 is assembled using the latest production technologies, including Zünd's digital cutting systems.

Zünd's digital cutting systems are helping to address these challenges by providing precision cutting and customizable workflow automation. By automating workflows, increasing efficiency, and optimizing the entire production process, manufacturers can reduce costs, improve quality, and increase profitability.

Overall, Zünd's digital cutting systems are proving to be a valuable tool for manufacturers in a range of industries, from aviation and aerospace to automotive, graphics, packaging, and more. By providing precision, flexibility, and automation, these systems are enabling manufacturers to optimize their production processes and stay competitive in a fast-paced and constantly evolving manufacturing environment.